|

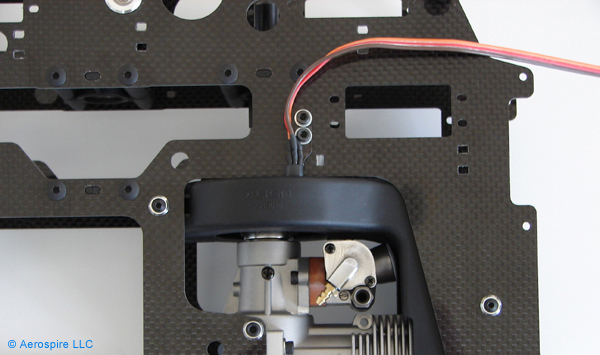

Align's T-Rex 600 Nitro

helicopter's cooling fan is upside down. As a result, the RPM

sensor is mounted on the frame. To nicely mount MultiGov's RPM

sensor, follow the instructions below. Note

that this is not the only way to do it; we decided to place the sensor

on the outside of the frame versus the inside for ease of adjustment,

replacement, and maintenance.

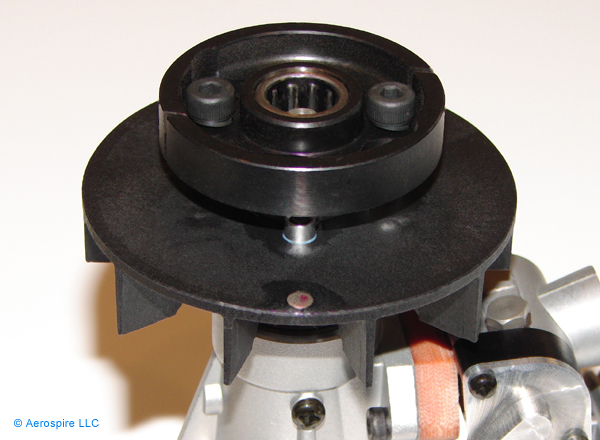

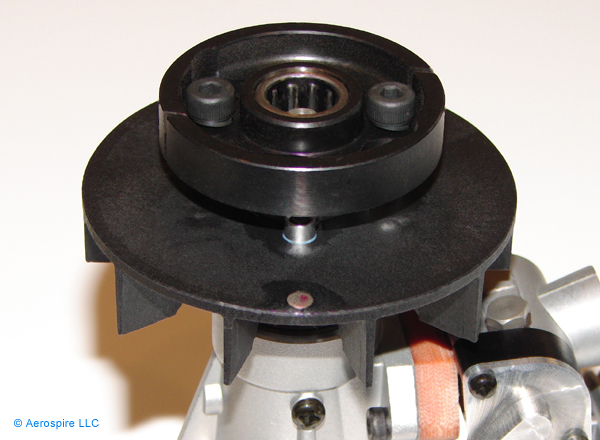

Using 5 or 30 minute epoxy, glue the magnet onto the fan.

Make sure you glue the magnet the correct polarity to match the sensor.

You want the magnet to be fully flush with the fan -- we put some epoxy

in the hole and used a long

nose plier to press the magnet in.

There are two ways we

suggest you mount your sensor. The first way is very simple

without using any brackets but you must be very precise on sensor

placement and bending the sensor. The second way is to modify one

of our included brackets for a more adjustable mount. We leave it

up to you to decide which way you want to go.

|

Method

1:

Simple Bracketless Installation |

Method 2:

Modified Bracket Installation |

|

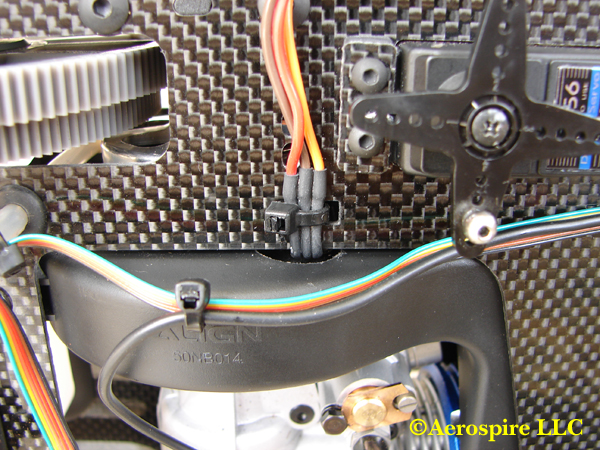

Step 1:

To mount the sensor outside the frame, enlarge the fan shroud

hole using a Dremel as shown in picture.

Step 2:

After you determine which way to bend the sensor, move fan with

the magnet to see exactly where the sensor needs to be bent so the

magnet runs directly over the sensor. This will typically be

farther out than when you mount the sensor on a bracket.

Step 3:

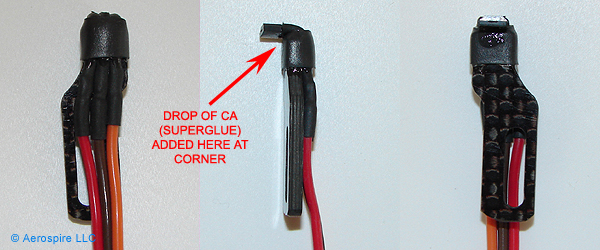

Bend the sensor and apply some CA (superglue) over the heat shrink

tubing so that the sensor wires essentially glue together.

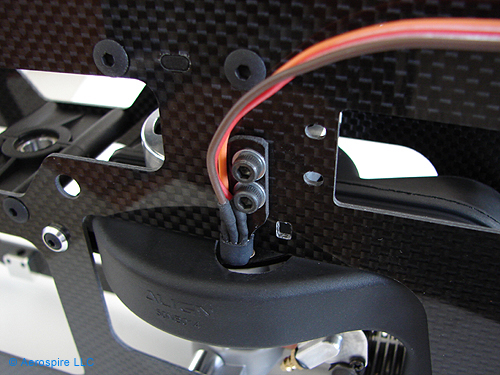

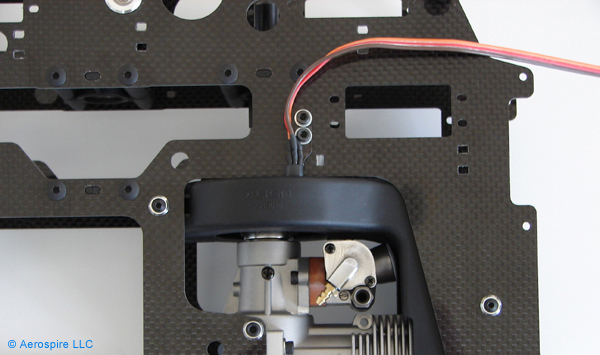

Step 4:

Using the included cable tie, position and secure the sensor

right in between the two holes already on the frame. You must

make sure that the magnet directly runs under the sensor chip, the

governor reads the magnet correctly, and that

there is adequate distance between the sensor and fan so they don't hit

(approximately 1.5-2 mm). For a more secure mount, add a drop

or two of CA between the sensor and the frame after the cable tie has

been tightened.

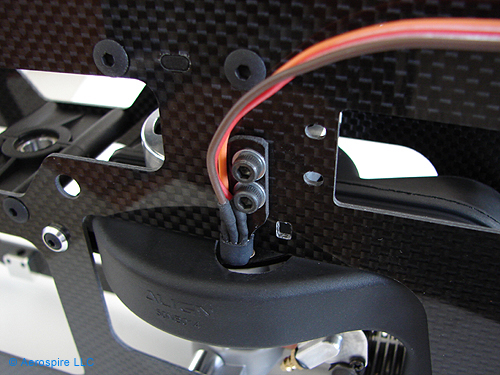

Completed simple sensor

installation.

|

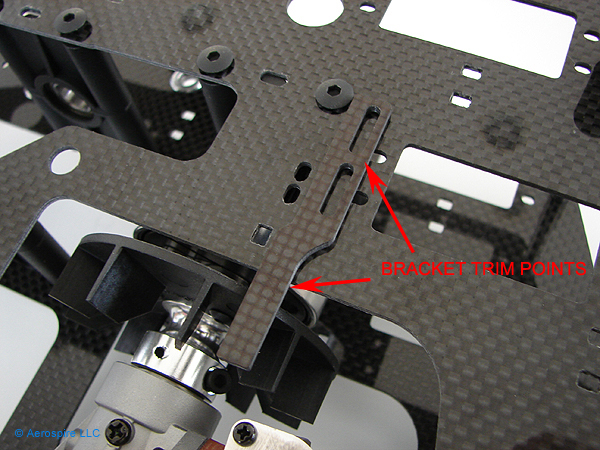

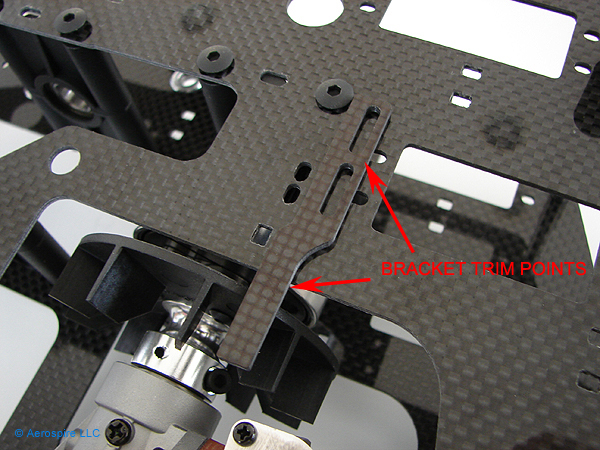

Step 1:

You will be cutting the smallest carbon fiber bracket included with MultiGov

to use as the mount. Place it over the frames to get an idea of

where to trim. The bracket will be cut shorter on

both ends.

Step 2:

Using a Dremel cutting wheel, trim the small bracket to resemble the

following. Approximately 17 mm was cut off the bottom of the

bracket to make it shorter. The top slot of the bracket was also

trimmed off. You should do a test placement first before actually

cutting as your bracket may differ slightly.

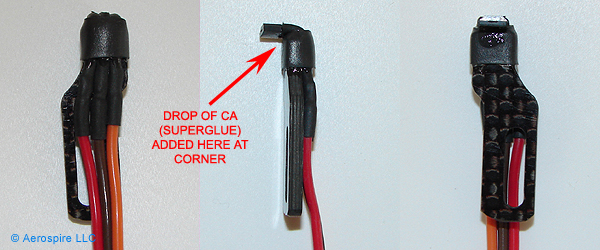

Step 3:

Attach the bent sensor onto the bracket using a small piece of adhesive

heat shrink included with MultiGov. Note that the sensor bend

point is a few millimeters below the chip. Also make sure you bend

it in the right direction to match the magnet polarity. Add a drop

of CA (superglue) at the joint for a more secure mounting. If

there is some heat shrink protruding past the top of the sensor, you can

trim it with an knife/razor blade so that it will not hit the fan later.

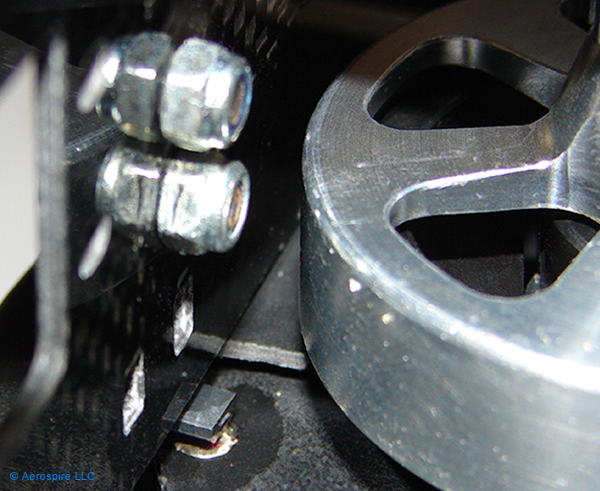

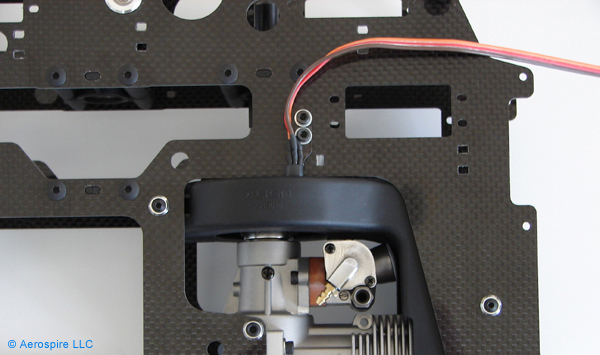

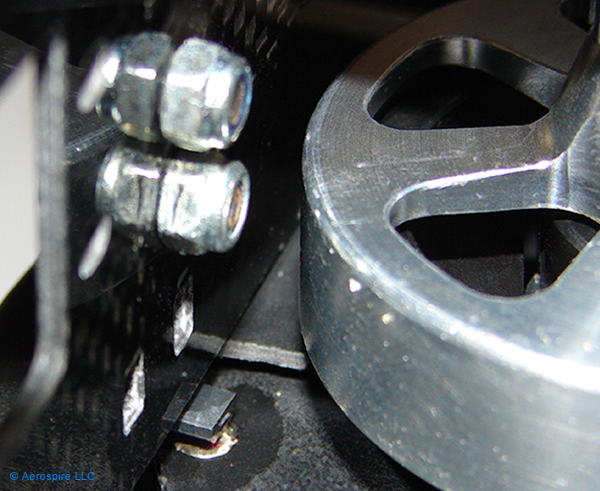

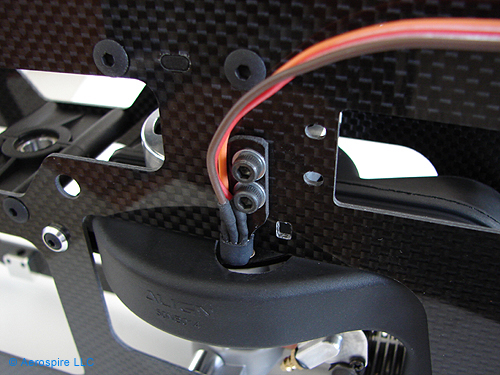

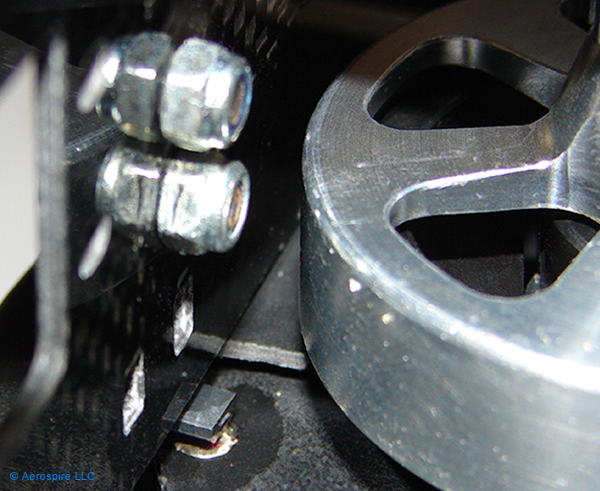

Step 4:

Place the RPM Sensor onto the frame using two bolts+washer+nuts.

We used two 3mm x 8 mm hex bolts with washers and locknuts. The

bolts fit perfectly through the existing two holes on the frame so no

drilling is needed. Trim

the fan shroud so that the sensor has adequate clearance and securely

tighten the bolts once you have a good sensor reading (sensor is approximately 1-2

mm directly above the magnet). Double check everything before you start the

motor for the first time after building the helicopter.

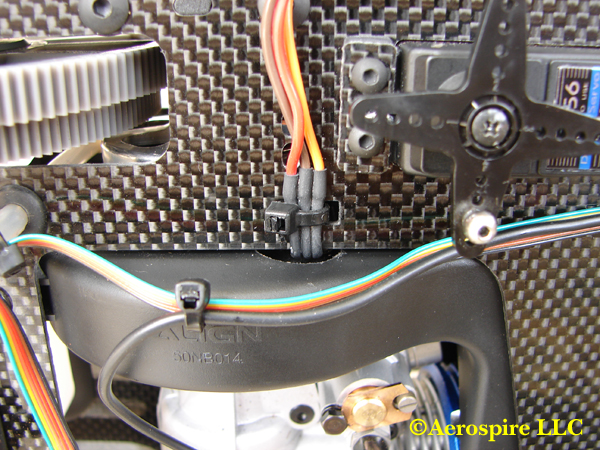

Completed installation.

|

METHOD

1: SIMPLE BRACKETLESS INSTALLATION

Step 1: To mount the sensor outside the frame, enlarge the fan shroud

hole using a Dremel as shown in picture.

Step 2: After you determine which way to bend the sensor, move fan with

the magnet to see exactly where the sensor needs to be bent so the

magnet runs directly over the sensor. This will typically be

farther out than when you mount the sensor on a bracket.

Step 3: Bend the sensor and apply some CA (superglue) over the heat

shrink tubing so that the sensor wires essentially glue together.

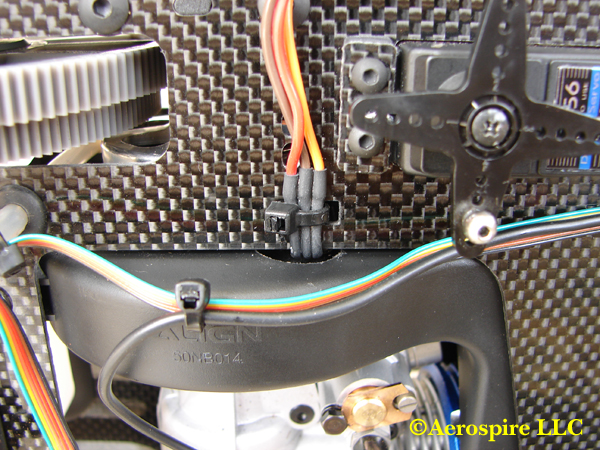

Step 4: Using the included cable tie, position and secure the sensor

right in between the two holes already on the frame. You must

make sure that the magnet directly runs under the sensor chip, the

governor reads the magnet correctly, and that

there is adequate distance between the sensor and fan so they don't hit

(approximately 1.5-2 mm). For a more secure mount, add a drop

or two of CA between the sensor and the frame after the cable tie has

been tightened.

Completed simple sensor

installation.

METHOD

2: MODIFIED BRACKET INSTALLATION

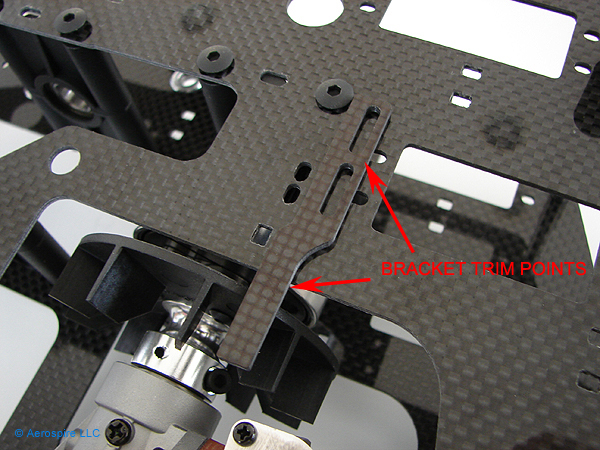

Step 1: You will be cutting the smallest carbon fiber bracket included with MultiGov

to use as the mount. Place it over the frames to get an idea of

where to trim. The bracket will be cut shorter on

both ends.

Step 2:

Using a Dremel cutting wheel, trim the small bracket to resemble the

following. Approximately 17 mm was cut off the bottom of the

bracket to make it shorter. The top slot of the bracket was also

trimmed off. You should do a test placement first before actually

cutting as your bracket may differ slightly.

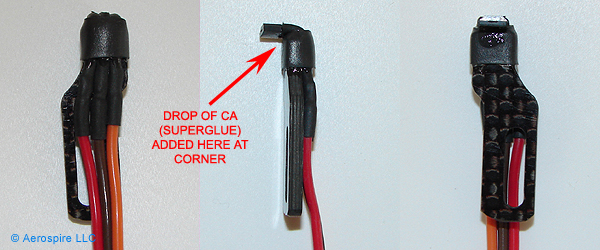

Step 3:

Attach the bent sensor onto the bracket using a small piece of adhesive

heat shrink included with MultiGov. Note that the sensor bend

point is a few millimeters below the chip. Also make sure you bend

it in the right direction to match the magnet polarity. Add a drop

of CA (superglue) at the joint for a more secure mounting. If

there is some heat shrink protruding past the top of the sensor, you can

trim it with an knife/razor blade so that it will not hit the fan later.

Step 4:

Place the RPM Sensor onto the frame using two bolts+washer+nuts.

We used two 3mm x 8 mm hex bolts with washers and locknuts. The

bolts fit perfectly through the existing two holes on the frame so no

drilling is needed. Trim

the fan shroud so that the sensor has adequate clearance and securely

tighten the bolts once you have a good sensor reading (sensor is approximately 1-2

mm directly above the magnet). Double check everything before you start the

motor for the first time after building the helicopter.

Completed installation.

|